UV Curing system Manufacturer

LED-UV technology has become a staple across diverse industries, complementing the presence of traditional UV lamps. Futansi provides an extensive array of LED-UV curing systems, encompassing spot sources, lamps, flood lamp, and linear units with varying dimensions and radiation profiles. Our expertise lies in crafting and evolving bespoke curing solutions to meet unique customer needs.

Wavelengths from 365 nm – 470 nm

Our UV LED wavelengths are available in UV-LED units are available in the wavelengths 365 nm, 385 nm, 395 nm and 405 nm, depending on unit and application also other wavelength are possible. Choose between air-cooled or water-cooled versions, which can be used in the clean room.

Advantages of LED Technology

LEDs do not emit IR irradiation. Due to the low temperature impact on the substrate also temperature-sensitive materials can be irradiated. As LEDs do not need any heating or cooling periods, LED-UV modules can be switched on and off whenever needed and are immediately ready for operation. LEDs have got a typical lifetime of more than 20.000 hours.

Application fields LED-UV units

The UV-LED technology is applied for pinning and final curing inks, varnishes and silicones as well as for bonding, curing and fixing UV adhesives and casting compounds. UV-LED systems are also used for finishing or coating web-type materials or 3D objects. Our LED-UV units are used for pinning and curing on narrow web but also on large format printing machines (sheet-fed offset printing, inkjet printing, flexo printing).

1、optical communication industry

2、photovoltaic new energy

3、semiconductor materials

4、medical devices

5、3C electronics

6、PCB circuit board

7、optical parts

8、laboratory materials

9、ink printing

The system features two operational modes:

- Admin Mode: Provides full device control for setting curing time and intensity cycles, allowing users to program and save specific curing profiles for future use.

- Production Mode: Offers a simplified interface for manufacturing staff to operate with ease.

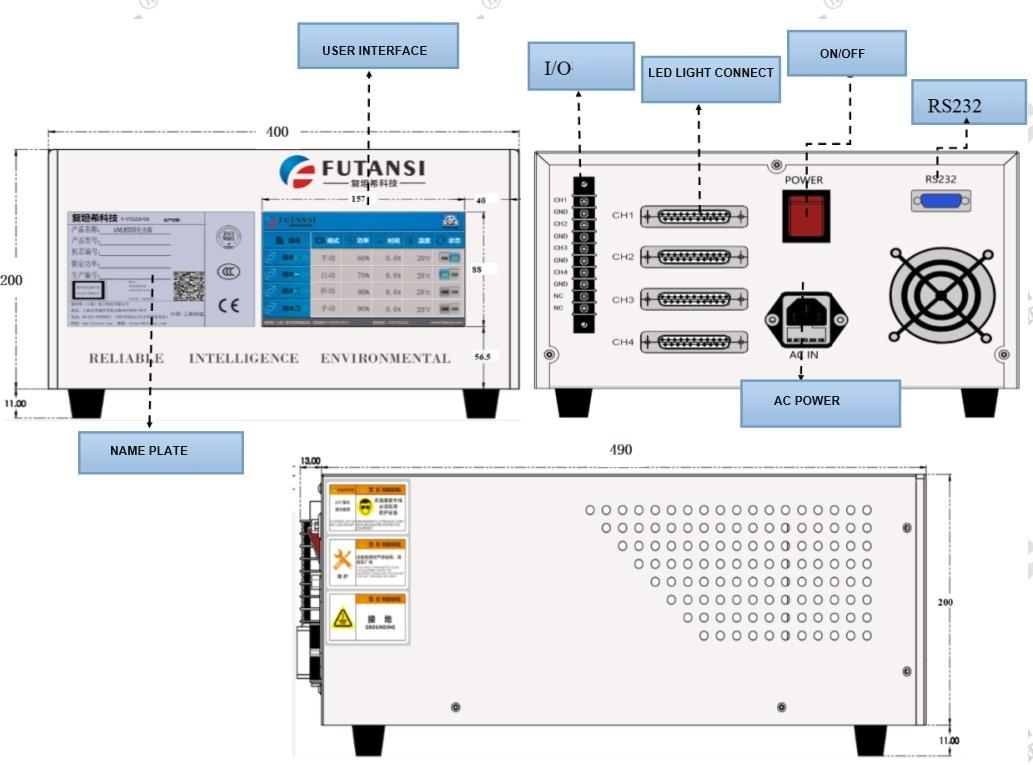

The complete UVSP81T system includes a controller/power supply and LED emitter, with wavelengths of 365, 385, 395, and 405 nm available. Various accessories can be integrated for specialized applications, and components are sold individually. Futansi provides a one-year warranty against material and workmanship defects from the purchase date.

Futansi also offers a Try-and-Buy program, allowing potential customers to test the light-curing systems free of charge for a two-week period.

Features

- High intensity

- Very high uniformity across entire cure area over a wide range of working distances

- LED emitters available in 365, 385, 395, and 405 nm or other wavelengths

- Admin and production modes

- Touch screen with full keyboard

- Instant on-off

- Efficient LED temperature management and system monitoring

- Remote I/O interface

Controller

Note: The controller package comes with a 2-meter interconnect cable for linking the controller and emitter. For longer distances, an additional interconnect cable can be purchased to extend the range without compromising performance.

Resources

![]() 350mm*350mm UV LED Flood curing system

350mm*350mm UV LED Flood curing system

![]() Futansi UV LED system User Manual

Futansi UV LED system User Manual

Further Advantages of LED-UV Compared to Conventional UV Technology:

- Compact size for easy installation

- Easy handling at clocked processes

UV Measuring Devices for LEDs

As a manufacturer of LED-UV units we have also developed an UV measuring device with LED-UV sensors to monitor the UV intensity on the substrate. For more information: UV radiometer